The circular economy in the battery industry

In a world with a diminishing supply of raw materials, MIDAC has set itself the ambitious goal of closing the life cycle of its products by reusing and recycling materials.

Minimum recycled battery quantity in line with the Battery Regulation EU 2023/1542.

Recycling numbers:

Technologies

(LFP and Cobalt)

Used batteries treated in the pilot line in 2025

Used batteries treated in the industrial facility in 2028

2nd Life numbers:

Types of modules (MIDAC and OEM)

Estimated accuracy of health status

2nd Life modules tested

Midac among the European leaders of IPCEI batteries

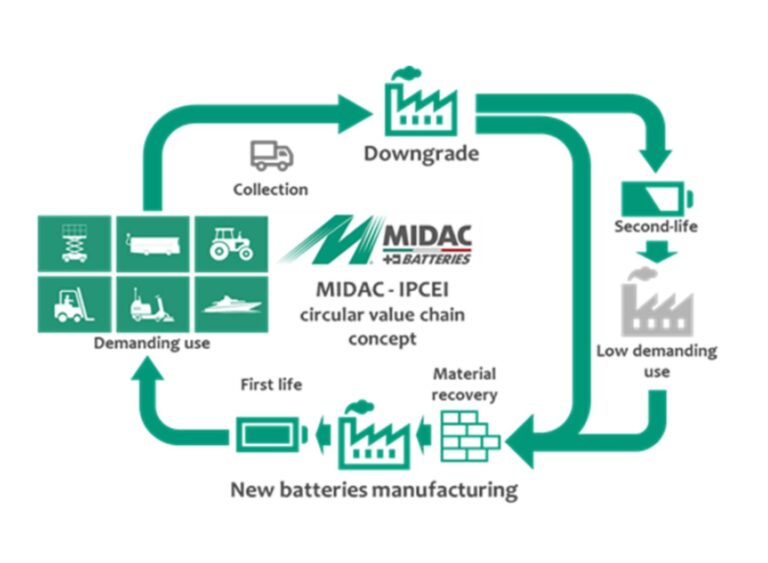

MIDAC is one of the sixty companies in the battery industry in Europe that participates in the IPCEI programme (Important Project of Common European Interest) programme for batteries which aims to implement the entire lithium battery chain in Europe.

With this programme, MIDAC intends to close the value chain of its batteries with a circular economy project that includes the reuse, recycling and production of new batteries starting with recycled materials.

To implement this ambitious programme, MIDAC will invest 130 million euros over seven years to create new production sites aimed at recycling and the production of lithium batteries in Italy.

From used battery to new raw material: the MIDAC project

The MIDAC project covers three of the four work streams in the IPCEI programme: Production of cells (WS2), Production of battery packs (WS3) and recycling and 2nd Life (WS4) for lithium batteries.

The project starts with the collection of used lithium-ion (LiB) batteries. MIDAC disassembles the battery packs to obtain the modules which will be selected through a proprietary protocol to assess their use in second life applications.

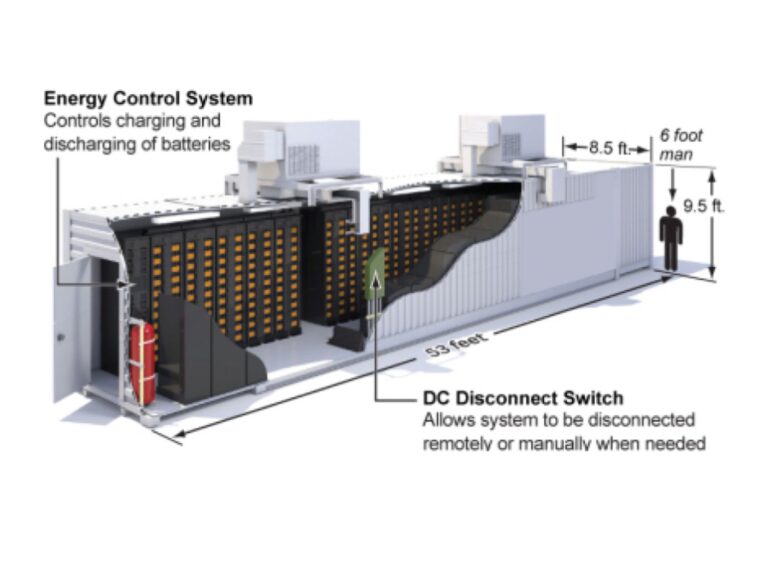

The duly selected modules that are suitable for a 2nd Life will be used to produce second life batteries used for stand-by storage. The modules that are not suitable for a 2nd Life will be used, through the construction of a recycling plant, to recover secondary raw materials for new cells, to then produce new first life industrial batteries.

The project

The 2nd Life project is aimed at developing techniques to differentiate and select used LiBs to reuse in secondary, less energy-intensive applications (e.g. stand-by applications) as new ‘second life’ products.

Recycling

Recycling is an important pillar to support the battery value chain in Europe. Together with other partners in the IPCEI project, MIDAC is developing a process that combines mechanical and hydrometallurgical treatments aimed at recovering up to 95% of the battery content, thus anticipating and exceeding the targets of the new Battery Regulation.

MIDAC will implement a pilot line to test the technology before building an industrial facility.

Production

Cell production is the final pillar. As part of the IPCEI, MIDAC aims to demonstrate that recycled materials can be used for the production of new Gen3B cells, achieving improved thermal properties and mechanical strength.

The impact

The impact that MIDAC expects from the implementation of the programme will be significant in creating a value chain of European batteries.

MIDAC will, therefore, develope a robust circular economy around lithium batteries and make significant advances in battery technology, thus positioning itself as an important player in Europe.

Press about our 2nd Life & Recycling projects

International Day of Clean Energy January 26 marks the International Day of Clean Energy, estabilshed by the United Nations. This

Battery Innovation Days We took part in the Battery Innovation Days in Graz (Austria), a unique event organized by the

World Sustainable Transport Day November 26 marks the World Sustainable Transport Day, established by the United Nations in 2023.This day

MIDAC IPCEI (Important Projects of Common European Interest) MIDAC will invest 130M€ in seven years among Lithium Battery value chain

Midac Role REUSE aims to investigate the “Second Life” application of Lithium Batteries in four different scenarios: Residential application, Industrial

Midac Role MIDAC in FLEXIndustries project holds the role of technical provider of an Energy Storage System in SUANFARMA plant